Silicones

Silicones (VMQ, PMQ, PVMQ)

Extreme temperature range stability and low temperature flexibility are characteristics of silicone compounds. Silicones provide outstanding resistance to compression set, sunlight, ozone, oxygen, and moisture. They are very clean and are used in many food and medical applications because they do not impart odor or taste.

Silicone can be compounded to be electrically resistant,

conductive or flame retardant.

Compound 71417C

- Minnesota Rubber’s most versatile silicone compound

- Excellent compression set properties

- Heat resistance to 450°F (232°C)

Compound 71115B

- Recommended for diaphragms and similar dynamic parts

- Heat resistant to 450°F (232°C)

Compound 74115

- High strength at low temperatures

- Performs well and remains flexible to -150°F (-101°C)

- High tensile strength and excellent tear resistance over a wide temperature range

| Compound | Hardness Shore A | Tensile MPa | Tensile psi | Elongation (%) |

|---|---|---|---|---|

| 71417C | 70 | 6.0 | 870 | 200 |

| 71115B | 50 | 8.3 | 1200 | 420 |

| 73117A | 70 | 4.8 | 700 | 170 |

| 74115 | 55 | 8.3 | 1200 | 450 |

As well as millable grade silicones, Minnesota Rubber and Plastics offers Liquid Silicone Rubber (LSR) molding. The LSR process offers design, cost and end-use options that complement and extend beyond the capabilities of millable grade materials. Minnesota Rubber and Plastics offers LSR compounds with hardness from 20 to 80 Shore A in different colors.

| LSR Compound (RED) | Hardness Shore A | Tensile MPa | Tensile psi | Elongation (%) |

|---|---|---|---|---|

| 76112 | 20 | 6.9 | 1000 | 300 |

| 76113 | 30 | 6.9 | 1000 | 300 |

| 76114 | 40 | 8.3 | 1200 | 300 |

| 76115 | 50 | 8.3 | 1200 | 300 |

| 76116 | 60 | 8.3 | 1200 | 300 |

| 76117 | 70 | 8.3 | 1200 | 300 |

| 76118 | 80 | 6.9 | 1000 | 300 |

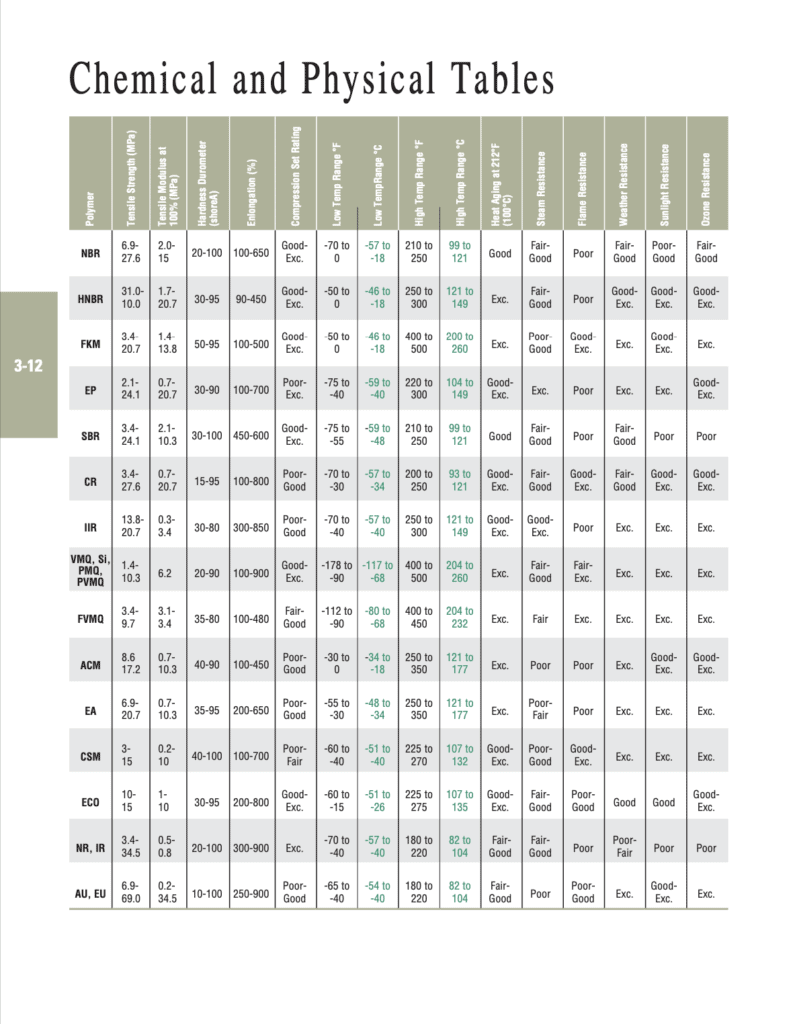

Chemical and Physical Tables

Click below to view the Elastomers/Materials: Chemical and Physical Tables PDF