Undercuts

An undercut feature of a part is one which projects back into the main body of the part.

As the undercut becomes deeper, it results in a part that is difficult, or perhaps impossible to remove from the mold.

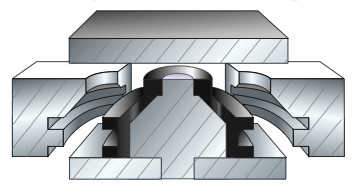

An extreme case of an undercut part is illustrated below, with the cross-section of a part in a mold. The mold, composed of three sections, opens vertically. In this example, it would not be possible to remove the part from the vertically-opening mold.

When an undercut feature is essential to the functionality of a part, it may be possible to design a mold that opens horizontally, as well as vertically, as shown in the following illustration. When removing the part from this mold, the center plate separates and the part slides out much easier than trying to pull the undercut feature through the center hole. These types of molds, however, are very costly to construct and operate, and result in a relatively high part cost.