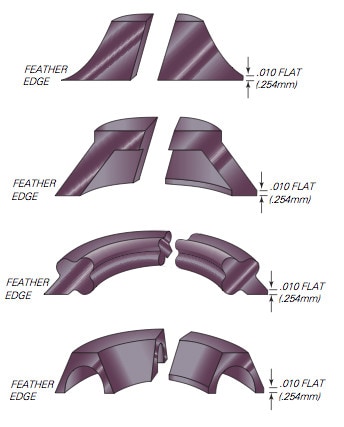

Sharp Edges

Wiper seals, lip seals, and similar parts are frequently designed with a sharp edge, referred to as a “knife edge” or “feather edge”.

It is difficult to hold such a thin edge in the molding process, as these edges tend to tear during removal from the mold. Normal de-flashing can also chip a sharp edge.

Unless a sharp edge is absolutely necessary, we recommend squaring off edges [.010 in (0.25 mm) minimum flat] to ensure clean surfaces on the finished product.