Custom Molded Rubber Manufacturer

We Develop and Manufacture Custom Molded Rubber Compounds and Components for Demanding Applications

Engineers in industries as diverse as food and beverage to medical trust Minnesota Rubber & Plastics for our custom molded rubber development and manufacturing capabilities.

When clients are facing tough molded rubber engineering challenges, they turn to us early in a project for our material science, design, and manufacturing expertise. The result: quick answers, multiple options and long-term project success. Our elastomer capabilities cover a wide range of materials including black rubber, gum stock silicone/High Consistency Rubber (HCR), and Liquid Silicone Rubber (LSR). With our science-based approach to solving problems, we specialize in designing and manufacturing close-tolerance components and assemblies that must comply with stringent federal regulations such as finished Class 1, 2, and 3 Medical Device product regulations.

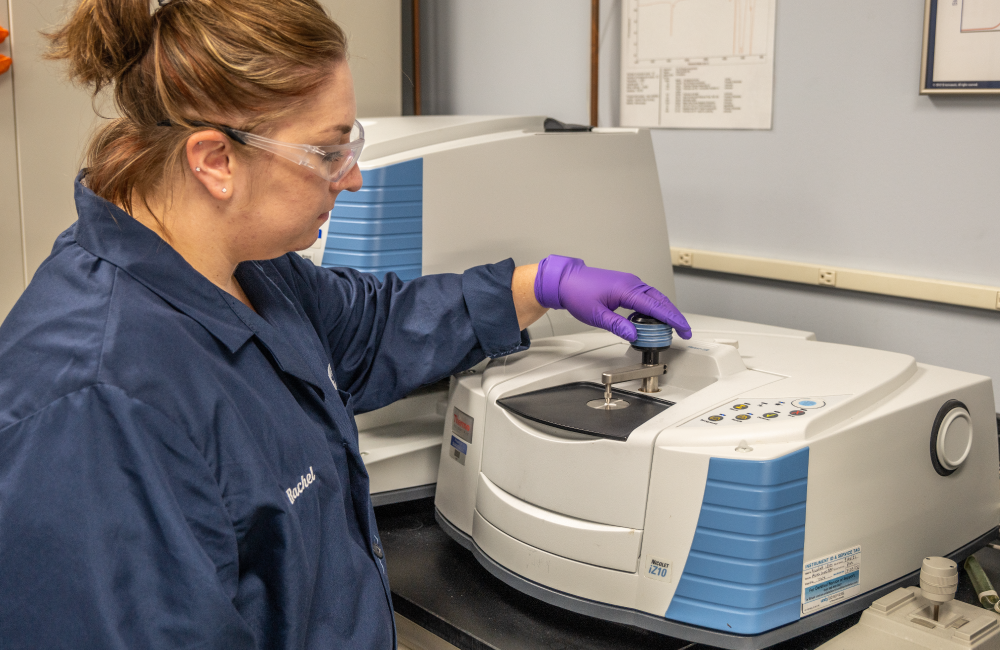

On-premise advanced materials lab saves time and costs

With our fully equipped materials lab, we’ll keep your projects on time and on budget if new custom rubber, silicone or polymers must be developed for a part or component. Additionally, we pull from a deep library of over 3,000 different existing portfolio compounds to meet a broad variety of customer requirements. The lab can quickly test up to 100 different compound samples without operator intervention. When required, we operate around the clock to meet your development and manufacturing needs—a critical service in a global economy where time zones are irrelevant.

Have a custom molded rubber project you’re working on?

Global manufacturing gives you more options for custom molded rubber

Your custom molded rubber components can be manufactured and supported at any one of several locations we have around the world: United States, Mexico, Europe and China. Our worldwide manufacturing facilities operate under strict ISO guidelines including ISO 13485, and ISO 9000. These facilities operate under a corporate-wide Environmental Management System registered to the International Standards Organization series ISO-14001.

Design Engineers: Read our Design Guide

We wrote this for design engineers because you don’t have time to become a rubber or plastics expert. That’s our job.

To gain a better understanding of the processes, materials and technical considerations involved in the design and manufacture of custom-molded rubber, read through our Engineer Design Guide. This comprehensive design tool details both rubber and plastic design issues including a materials overview and prototype mold design considerations.